Application engineering Services

Alcon offers a fully integrated package of application engineering solutions for cutting tools, industrial knives, and more. Let us connect you with our expert, in-house tool and die engineering experts. From managing a custom project start to finish or providing feedback on how to enhance performance of existing tooling, partner with Alcon’s application engineers to ensure the very best results.

Alcon offers application engineering services you can trust

When it comes to engineering cutting tools and blades, depend on Alcon’s extensive application engineering and technical operations staff for:

- Reverse engineering

- Product development

- Metallurgical analysis

- Design collaboration

Our broad network of established relationships with specialty process suppliers and tooling reps ensure we can consistently offer the most advanced tool manufacturing capabilities and value-added features available.

Reverse Engineering services

When you need original equipment manufacturer (OEM) machined parts, turn to Alcon Tool Company. With decades of experience in reverse engineering industrial knives, we can meticulously deconstruct and analyze the precise specifications, materials, and design elements of any OEM machine blade, ensuring the seamless reproduction and enhancement of cutting tools for various industries.

By leveraging our state-of-the-art technology, industry expertise, and a deep understanding of OEM machine knife requirements, Alcon’s reverse engineering services will help you reduce downtime and maintain optimal operational performance.

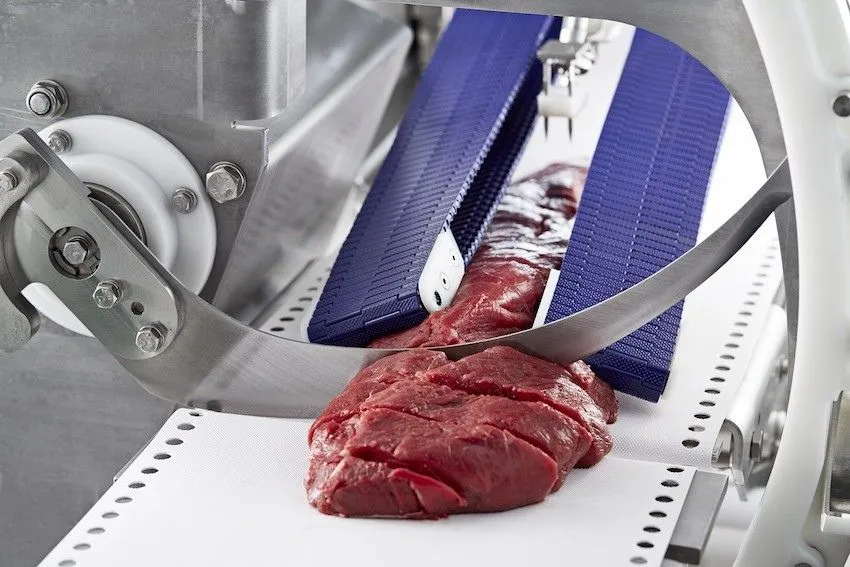

Machining Solutions for Food Processing, Paper & Packaging Equipment

At Alcon Tool, our engineers–in tandem with automated 5-axis mill and CNC machining team–provide unmatched reverse engineering of blades for OEM machines in food processing and paper / packaging / converting. Our goal: maximizing the efficiency, precision, durability, and reliability of our customers’ cutting operations.

Reverse Engineering for Food Processing OEM Machines

We understand the intricate designs and engineering principles behind complex food processing machinery produced by these leading companies:

- Marel

- Stork Food Processing Machines

- Meyn

- Food Craft Technologies

- Simmons Engineering

- Toby Slicer Blades

- Nu-Meat Technology

- Reiser

Our food processing blades are made from food-grade stainless steel–which is durable, resists corrosion, complies with food safety regulations, and withstands stringent sanitation requirements. Available with custom edge geometry for any cutting, slicing, or dicing task, our machine knives are sharp and efficient in cutting meat and other food products with different textures and densities, minimizing product damage and maximizing clean cuts.

Reverse Engineering for Paper / Packaging / Converting OEM Machines

Within in the paper / packaging / converting industry, we have supported the advanced machinery produced by:

- Eberle

- Pakea

- Elsner Engineering

- Appleton

- Maxcess International

- Brodbeck

- Coretech

- Parkinson Technologies

Depending on your application and desired durability, our paper, packaging, and converting equipment knives can be made from various materials–such as high-speed steel, tool steel, or carbide–and have specific edge geometries tailored for cutting or perforating materials like paper, cardboard, or plastic films with accuracy and minimal material waste.

THE ALCON ADVANTAGE WITH REVERSE ENGINEERING

Our reverse engineering services uphold and build upon each OEM’s unique engineering approach. Our work guarantees cutting-tool compatibility for your equipment and adaptability to changing industry requirements while preserving the quality and dependability of your machine.

With a reverse-engineered OEM machine knife from Alcon Tool, you can sustain and potentially increase efficiency and innovation in your day-to-day operations.