Home Services and Capabilities

Services & Capabilities

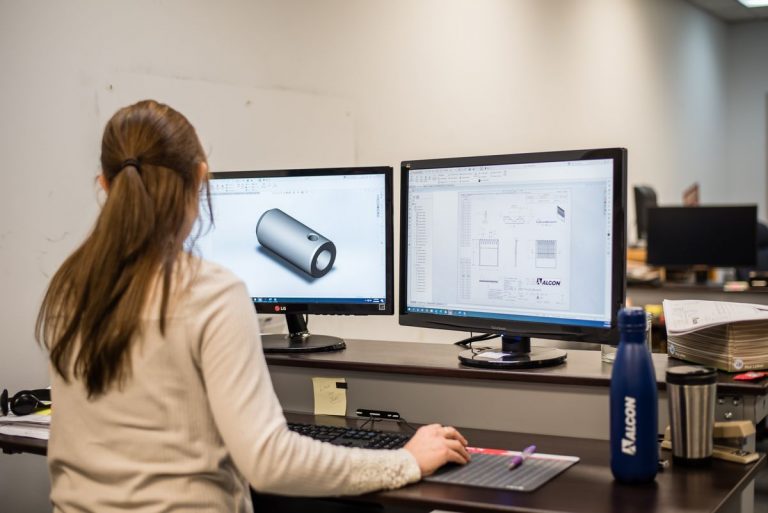

At Alcon, we know and value the primary value of “Relationship.” Commitment to the highest level of quality and craftsmanship throughout all stages of our production process is driven by our desire for customer satisfaction. We have a passion for creating value for our customers in the form of reliable, high quality tooling that is custom designed to optimize efficiency in your production process. Our in-house engineering and production capacities, guided by expertise of metallurgy, blade design, and cutting dynamics provide Alcon a distinct competitive advantage in providing our customers the highest quality cutting tools to allow them to focus on what they do best.